OEMs and contractors prefer Browning products not just for their longevity, but because of the tools that are available to connect you with our engineering specialists, including the Belt Drive Audit tool in the Toolbox Technician® app. Once you input your air handing drive information, our technical engineers calculate the best optimized drive for your application, complete with ROI. Online, our Edge™ (Engineered Design, Guaranteed Economy) V-Belt drive optimization software also helps to select the lowest cost, most torque dense drives to improve the performance of your air handling equipment by maximizing efficiency and generating optimal air flow while requiring the least amount of energy.

Helical shaft-mounted speed reducers and in-line gear reducers are built to keep out contaminants and eliminate as much unplanned downtime as possible. We’ve engineered innovative bushing systems over decades for ease of installation and maximum shaft locking capacity.

Featured Product Categories

TorqTitan Belts

No Need to Re-Tighten the Titan! New Browning TorqTitan™ Belts contain new materials and the use of advanced-design technology that have led to a new generation of raw edge V-belts that outperform all similarly sized belts in a wide range of applications.

BOA™ Concentric Locking Collar

A modular bearing assembly consists of a sealed and lubricated inch or a metric ball bearing. It is contained within a variety of housings types, locking mechanisms, mounting styles, and housing materials.

TorqTaper Plus

Browning® TorqTaper Plus® shaft mounted reducer gearboxes are designed with a systematic approach for maximum life in rugged industrial environments. The patented design that allows ease of installation and removal.

Sealmaster And Browning: The Standard For Sealed Bearings

Customers choose mounted bearings because they are easy to install, able to fit most equipment and have lower costs. You’ll typically see two of these units installed on each end of the shaft. The bearings support an applied load while operating at some speed (measured in revolutions per minute). Bearings come in a variety of housing style options such as pillow block, 2 or 4-bolt flanges, take-up units, flange brackets, and others.

Seals Keep Bearings Safe

Regardless of housing type, they’re exposed to different potential environmental issues such as heat, outside elements, dirt, moisture and other contaminants. Seals are an integral part of bearing design, helping protect the bearing from environmental hazards and contaminants. If contaminants do make it past the seal, that could lead to lubrication issues and damage to rolling surfaces, resulting in poor and unsatisfactory performance.Browning And Sealmaster Set The Standard In Bearing Seals

Regal Rexnord’s Browning and Sealmaster brands have mounted bearings with suitable seal options for any application.

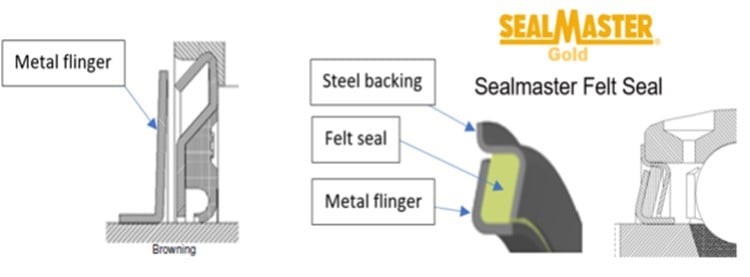

Browning mounted ball bearings have a single lip contact seal with a metal flinger to help fan away potential debris. Browning’s standard seal design is comparably used by other top tier 1 bearing suppliers.

Sealmaster offers felt seals for its standard units as well as other types of heavy-duty seal options. The Sealmaster felt seal design is a 3-component system:

- A gauge steel backing pressed inside the outer ring’s land diameter

- A gauge steel flinger press-fitted to its inner rings outside diameter

- A felt seal material located between the 2-gauge steels.

This unique sealing system traps debris while allowing purged grease at re-lube to expel potential contaminants that might have entered the bearing. Press-fitted seals also provide greater holding power as an important feature, preventing possible dislodging due to grease pressure at re-lube. Unlike seals snapped on to the outer ring groove, care should be taken to limit grease pressure as this could cause seals to be dislodged. In this condition, contaminants could readily enter the bearing, compromising lubrication and eventually leading to possible seizure.

Seal Options For Different Environments

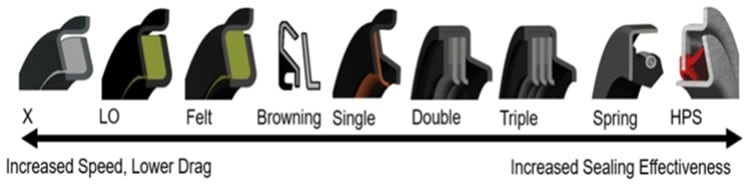

In most applications, a bearing’s useful life depends on how effectively the seals are maintained to seal off contaminants. Exposure to dirty or wet environments requires a more robust or heavier duty type seal. Resolving these issues requires a range of options to meet the demands in the application. Sealmaster offers these options with increasing seal effectiveness, as illustrated below from low drag “X” to heavy duty “HPS” seals.

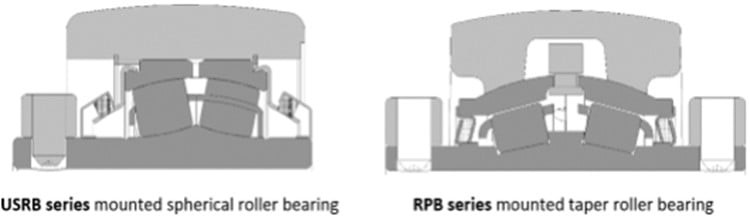

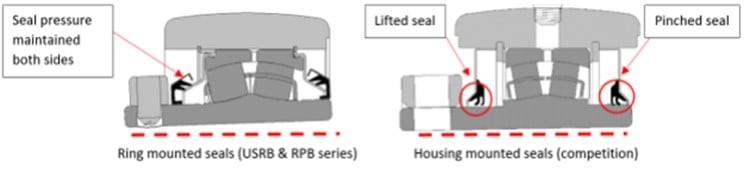

Sealmaster’s mounted roller bearings use a similar concept to the felt seal design for mounted spherical roller bearings (in the USRB series) and mounted taper roller bearings ( in the RPB series). For wet applications, contact lip seals are used as an option.

Both the USRB and RPB product lines have inner ring mounted seals versus housing mounted seals. This maintains seal pressure regardless of misalignment condition. During misalignment, a housing mounted seal could be pinched on one side while lifting the seal on opposite side. When this happens, the pinched seal may cause increased contact pressure while the raised seal could cause a gap, allowing potential contaminants to enter the bearing.