|

Morse® products have been a key component in the power generation, material handling, pulp and paper, and forestry industries. The Morse chain drives, mechanical clutches, and worm gearing and couplings have helped keep America rolling for over 125 years in the most demanding applications. Morse Regal Rexnord is a renowned brand recognized for its excellence in mechanical power transmission and conveying solutions. With over a century of expertise, it has consistently delivered innovative products and services across various industries. Specializing in chains, gears, couplings, bearings, and conveying equipment, Morse Regal Rexnord has established itself as a trusted partner for reliable and efficient machinery operation. Its products are known for their durability, precision engineering, and ability to withstand harsh operating conditions. The brand's commitment to quality is reflected in its rigorous testing procedures and adherence to international standards. Morse Regal Rexnord's comprehensive product portfolio caters to diverse applications, including manufacturing, mining, agriculture, and food processing. Beyond products, the brand offers comprehensive technical support, maintenance services, and customized solutions to meet specific customer needs. With a global presence and a network of distribution partners, Morse Regal Rexnord ensures prompt delivery and responsive customer service worldwide. Continuously investing in research and development, the brand stays at the forefront of technological advancements, driving efficiency, and productivity for its customers. Through its dedication to innovation, reliability, and customer satisfaction, Morse Regal Rexnord remains a leader in the mechanical power transmission industry. |

MOISTURE GUARD® CHAIN

FeaturesCHAIN TYPES: Most Morse® chain styles are available in corrosion resistant materials.

M SERIES CLUTCH

Features

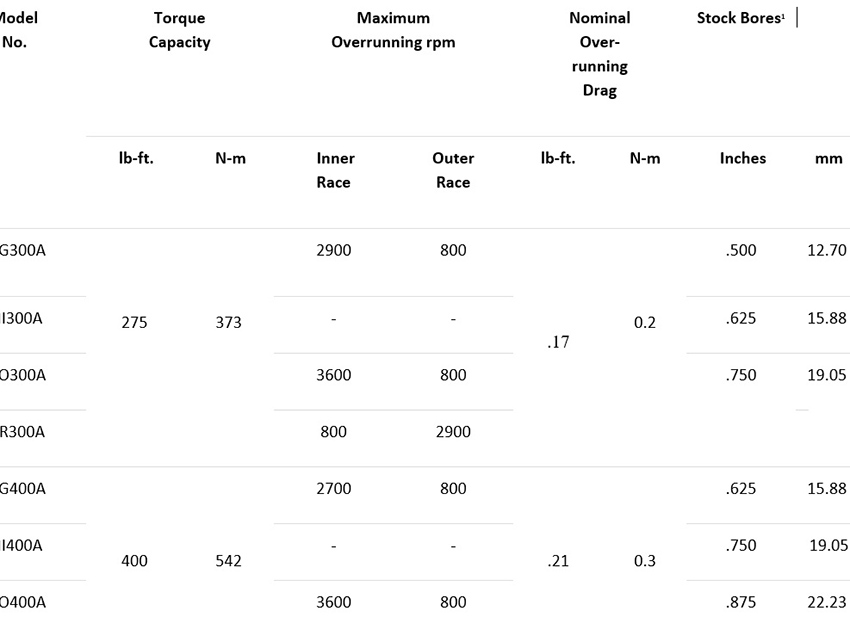

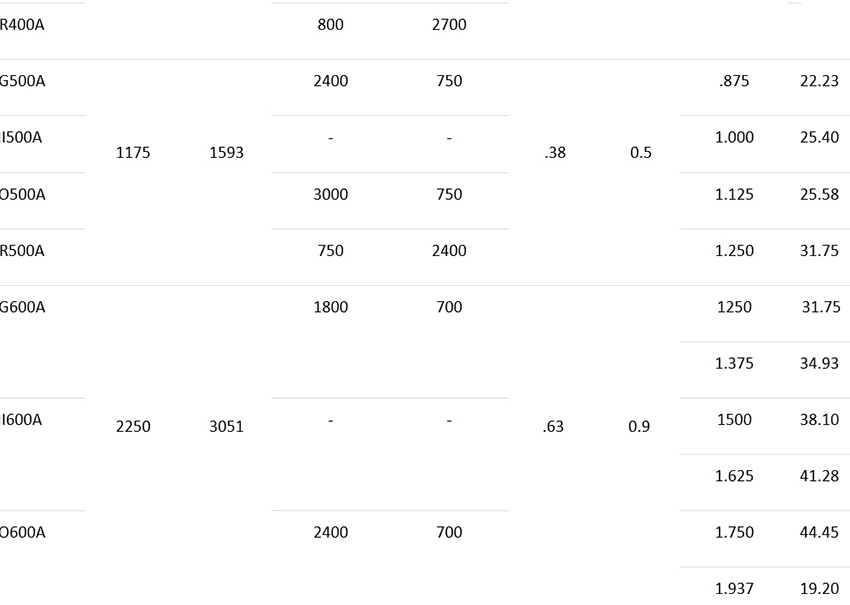

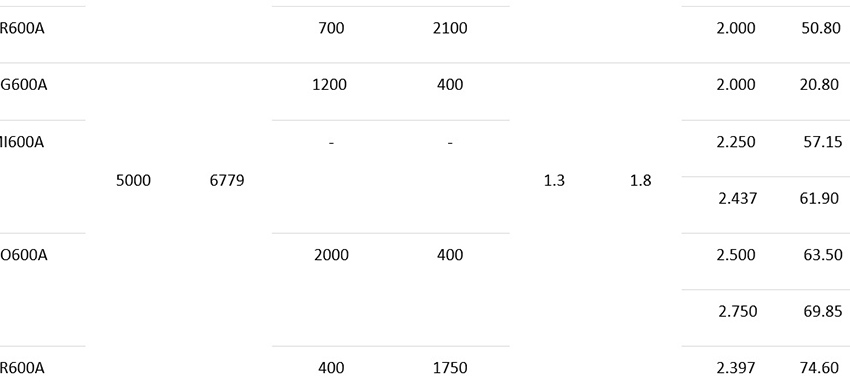

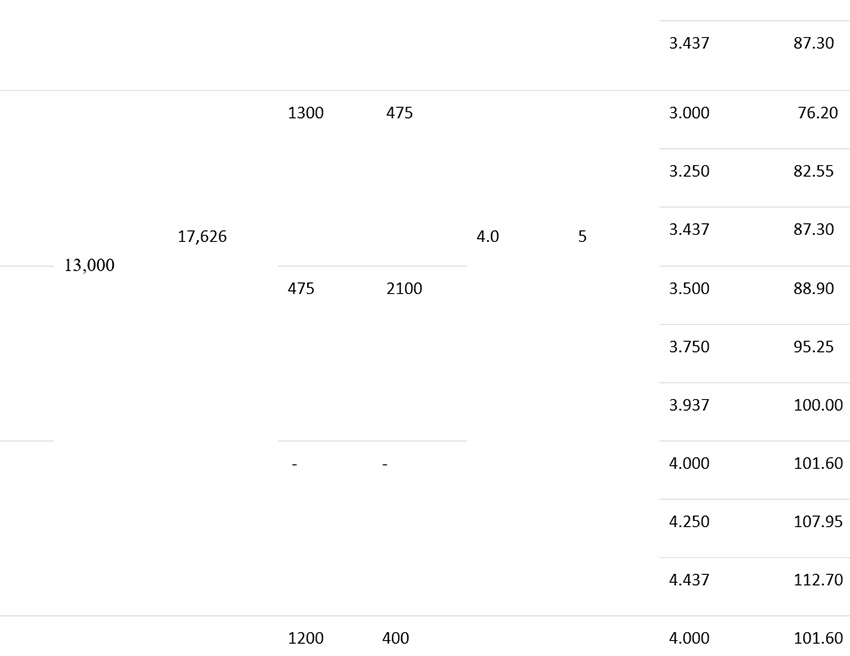

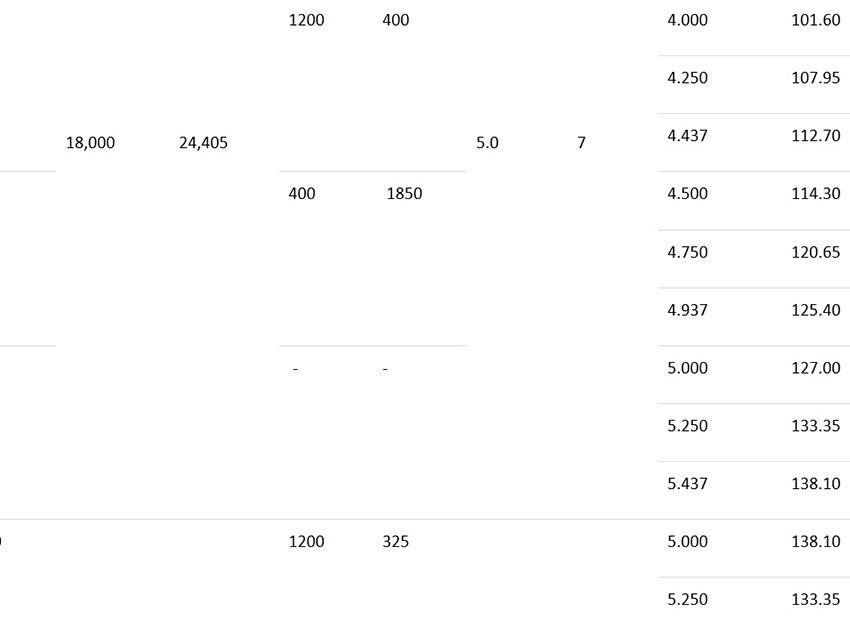

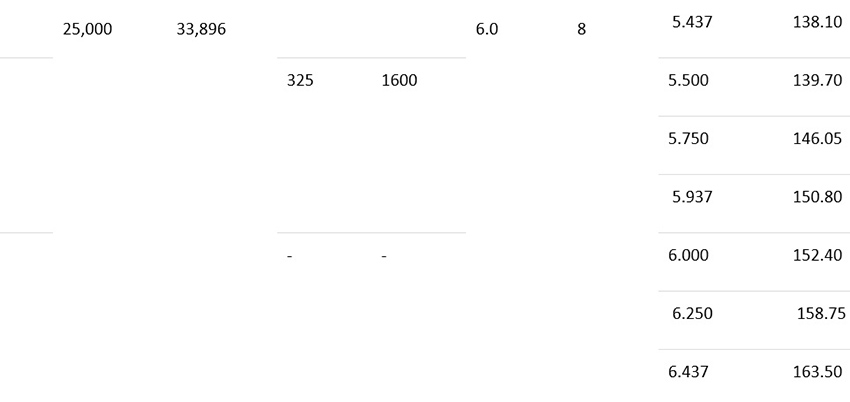

SpecificationsBore Range: 0.500" - 6.437" Download Related PDF Documents for more product information

M Series clutches incorporate a dual ball bearing supported design that includes high-quality hardened, precision formed and finished steel cams in a cage. The cam cage assembly is engineered for optimum performance and increased capacity. This clutch design provides for the most custom configurable and versatile clutch offered in the industry. The dual bearing design maintains race concentricity to help provide the most uniform loading of the cams. The M series clutch is designed to mount on through shafts that are secured to the shaft by a matching key provided with each stock bore clutch. Oil lubrication is standard, and grease lubrication is available at no additional cost. This general purpose clutch is intended for backstopping, indexing and overrunning (inner and outer race) applications. There are four different versions: MG, MI, MR and MO, each customized to specific applications. A full line of accessories are also available to accommodate many different applications:

Additional Data

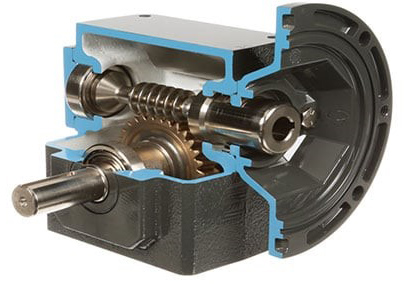

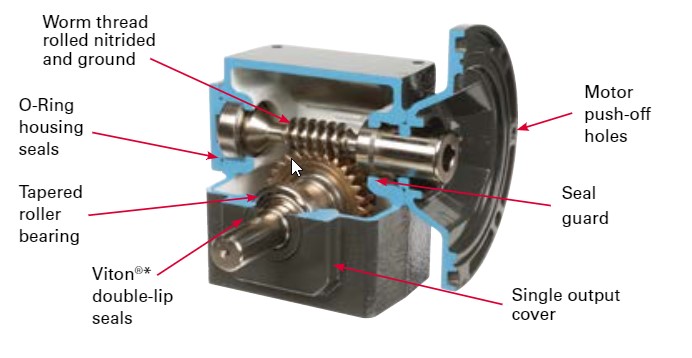

RAIDER® PLUS WORM GEAR REDUCERS

We know the odds of quick gearbox availability from finished stock are against you. The Morse® Raider® Plus worm gear reducer offers reliable design, support and is a drop-in replacement. Switching to Raider Plus worm gear reducers can make maintenance stress-free and maximize uptime in your facility. Features:

Benefits:

The Raider Plus worm gear reducer offers a large variety of add-on accessories and four available styles for flexibility. Both the universal style ("U"-style, shaft input) with an output shaft and the c-face style ("Q"-style, input quill) with an output shaft are available. Both the "U" and "Q" styles are also available with hollow outputs. The Raider Plus worm gear reducer is designed as an industry interchange and is dimensionally interchangeable with the major industry competitors. The Raider Plus worm gear reducer product line features a center distance range from 1.0" to 6.0" with ratios from 5:1 to 60:1. It also contains an output torque range from 200 to 10,000 ft-lbs. Additionally, the line is an industry leader due to its patented design technology and manufacturing techniques. 7 Ways The Morse Raider Gearbox Creates Stress-Free Maintenance1. Motor Push Off HolesReduce headaches and save time when removing the motor using the push off holes. This feature greatly helps when fretting corrosion is present in the quill input style as fretting hinders motor removal. 2. Seal GuardLess risk of input seal damage during transit, installation or storage. It saves you time as replacing a seal can take one hour or more. 3. O-Ring Housing SealsImproved leak prevention for less mess and longer life as gearbox will better retain lubricant and an o-ring is more reliable than a gasket. 4. Worm Thread Rolled, Nitrided And GroundOther gearbox designs just roll the worm thread, the Raider worm gear box is also ground, which creates a smoother, quieter operation and overall better performance and longer life. 5. Single Output CoverThe Raider gearbox has a cast closed housing on one side which is one less place it can leak. 6. Viton®* Double-Lip SealsImproved seal life. Viton seals have higher upper and lower temp limits, which enables longer life in a standard plant environment. 7. AvailabilityMake an easy transition to the Morse Raider gearbox with a Gap Walk® consultation for reliable design and availability. * Viton is believed to be the trademark and/or trade name of The Chemours Company FC, LLC, and is not owned or controlled by Regal Rexnord.

|

![]()

Harchandrai

House,

81 Maharshi Karve Road, Marine Lines, Mumbai - 400 002, INDIA.

Tel.: 91 - 22 - 22089090 / 22018438 / 66337300 /

6359091 / 66361376 / 22087654

E-Mail: harchandraisons@gmail.com |

Website: www.harchandrai.com